Solid-State Batteries: What 2025 Holds for Commercial Energy Storage Solutions

Solid-state batteries are projected to significantly advance commercial energy storage by 2025, promising enhanced safety, increased energy density, and improved efficiency across various sectors.

The landscape of energy storage is on the cusp of a profound transformation, with solid-state batteries 2025 emerging as a potential game-changer. This innovative technology promises to redefine how we power everything, from electric vehicles to grid-scale storage, offering a safer, more efficient, and potentially more sustainable alternative to conventional lithium-ion batteries. What exactly can we expect from this burgeoning technology in the near future?

Understanding solid-state battery technology

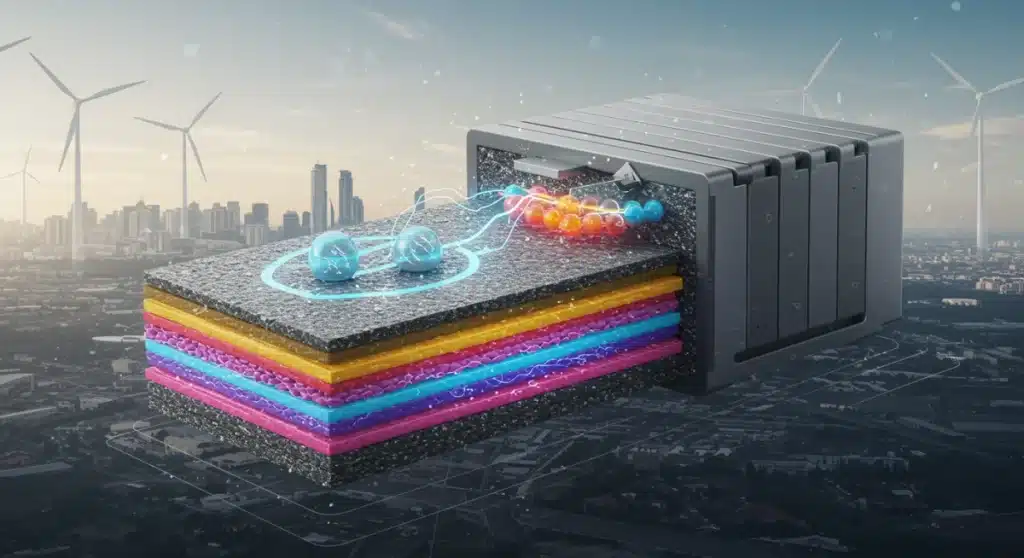

Solid-state batteries represent a significant leap forward from their liquid-electrolyte counterparts. By replacing the flammable liquid or gel electrolyte with a solid material, these batteries inherently offer enhanced safety, reduced risk of thermal runaway, and greater energy density. This shift in fundamental design unlocks a host of possibilities for various applications.

The core principle of solid-state batteries involves the use of solid electrodes and a solid electrolyte. This solid-state design eliminates the need for bulky separators and cooling systems often required in traditional lithium-ion batteries, allowing for more compact and lightweight battery packs. Such an innovation is critical for sectors where space and weight are at a premium, such as in electric vehicles and portable electronics.

Key components and their roles

Solid-state batteries are composed of several critical elements that differentiate them from liquid-electrolyte batteries. Understanding these components is essential to grasp the technology’s advantages and challenges.

- Solid Electrolyte: This is the defining feature, replacing the liquid electrolyte with materials like ceramics, polymers, or sulfides. It facilitates ion transfer between electrodes while preventing dendrite formation.

- Anode: Often made of lithium metal, which offers significantly higher energy density compared to graphite anodes in Li-ion batteries. This allows for more energy storage in a smaller volume.

- Cathode: Similar to Li-ion batteries, various cathode materials can be used, such as nickel-manganese-cobalt (NMC) or lithium iron phosphate (LFP), customized for specific performance needs.

The unique combination of these components allows solid-state batteries to operate at higher temperatures and withstand greater mechanical stress, contributing to their impressive safety profile and potentially longer lifespans. This also opens avenues for faster charging, as the solid electrolyte can often handle higher current densities without degradation.

In essence, solid-state battery technology is not merely an incremental improvement but a fundamental redesign aimed at overcoming the inherent limitations of liquid-based battery systems. The implications for commercial energy storage are vast, promising more reliable and robust power solutions across numerous industries.

The promise of enhanced safety and energy density

One of the most compelling advantages of solid-state batteries lies in their inherent safety and significantly higher energy density. These two factors are critical for widespread adoption across commercial sectors, particularly in applications where performance and reliability are paramount.

Traditional lithium-ion batteries, while powerful, carry a risk of thermal runaway and fire due to their flammable liquid electrolytes. Solid-state batteries mitigate this risk almost entirely by using non-flammable solid electrolytes. This eliminates the possibility of electrolyte leakage and significantly reduces the chance of internal short circuits, making them a much safer option for both consumers and industrial applications.

Beyond safety, the increased energy density of solid-state batteries is a game-changer. By utilizing lithium metal anodes, these batteries can store substantially more energy in a smaller and lighter package. This translates directly into longer operating times for devices, greater range for electric vehicles, and more compact energy storage systems for grid applications. For instance, an electric vehicle equipped with solid-state batteries could potentially travel hundreds of miles further on a single charge compared to a similar vehicle with conventional lithium-ion batteries.

Applications benefiting from improved safety and density

The enhanced safety and energy density characteristics of solid-state batteries make them ideal for a variety of high-impact commercial uses.

- Electric Vehicles (EVs): Longer range, faster charging, and reduced fire risk are crucial for mass EV adoption.

- Aerospace: Lighter, more powerful batteries are vital for drones, electric aircraft, and space applications where weight is a primary constraint.

- Grid Storage: Safer and more compact energy storage solutions can be deployed closer to urban areas, enhancing grid stability and renewable energy integration.

The ability to pack more energy into a smaller volume also reduces the overall footprint of energy storage installations, making them more versatile and easier to integrate into existing infrastructure. This is particularly relevant for urban environments where space is often limited, allowing for distributed energy resources that can support local grids.

Ultimately, the dual benefits of enhanced safety and higher energy density make solid-state batteries a profoundly attractive proposition for the future of commercial energy storage. These improvements address critical limitations of current battery technologies, paving the way for new innovations and broader adoption.

Manufacturing challenges and breakthroughs

While the promise of solid-state batteries is immense, their commercialization is contingent on overcoming significant manufacturing challenges. The transition from laboratory prototypes to mass production requires innovative solutions for scalability, cost reduction, and quality control. These hurdles are complex but are being actively addressed by researchers and industry leaders worldwide.

One of the primary manufacturing challenges involves creating a stable interface between the solid electrolyte and the electrodes. Achieving good contact across these solid materials is crucial for efficient ion flow and prevents degradation over time. Unlike liquid electrolytes that naturally conform to electrode surfaces, solid electrolytes require precise engineering to ensure optimal performance. This often involves high-pressure manufacturing processes and specialized materials that are difficult to produce at scale.

Another hurdle is the cost of materials and production processes. Many of the advanced solid electrolyte materials are expensive to synthesize, and the manufacturing techniques required are often more complex than those used for traditional lithium-ion batteries. Reducing these costs through material innovation and process optimization is vital for solid-state batteries to compete economically in the commercial market.

Recent breakthroughs in production

Despite these challenges, significant progress is being made, bringing solid-state batteries closer to commercial reality.

- Improved Electrolyte Synthesis: Researchers are developing new methods to synthesize solid electrolytes more efficiently and at a lower cost, often leveraging ceramic or polymer-based materials that are easier to scale.

- Advanced Stacking Techniques: Innovations in battery cell stacking and packaging are improving interface contact and reducing manufacturing complexity, leading to higher performance and reliability.

- Automated Production Lines: Investments in highly automated production facilities are aimed at mass-producing solid-state cells with consistent quality and reduced labor costs, mirroring the advancements seen in lithium-ion battery manufacturing.

Several companies are now reporting successful small-scale production trials and are investing heavily in pilot lines to refine their manufacturing processes. These breakthroughs suggest that while mass production remains a challenge, the industry is on a clear path towards overcoming these obstacles. The coming years will be crucial in demonstrating the scalability and economic viability of these new manufacturing techniques.

The journey from concept to widespread commercialization for solid-state batteries is marked by continuous innovation in manufacturing. The breakthroughs achieved thus far demonstrate a promising trajectory, suggesting that by 2025, we could see initial large-scale deployments in select commercial applications.

Commercial applications by 2025

The year 2025 is anticipated to be a pivotal moment for the commercial deployment of solid-state batteries. While full-scale mass adoption across all sectors may still be a few years away, several key industries are expected to begin integrating this advanced technology into their products and services. These early applications will demonstrate the practical benefits and pave the way for broader market penetration.

Electric vehicles (EVs) are likely to be among the first major beneficiaries. Several leading automotive manufacturers have announced plans to introduce EVs powered by solid-state batteries around 2025. These vehicles are expected to offer significantly improved range, faster charging times, and enhanced safety features, addressing some of the primary concerns that currently limit EV adoption. The initial rollout will likely focus on premium models or niche markets, serving as a proving ground for the technology before wider deployment.

Beyond automotive, portable electronics could also see early integration. Devices such as high-end smartphones, laptops, and wearables could benefit from the increased energy density and improved safety, leading to longer battery life and more compact designs. The smaller form factor and reduced thermal management requirements of solid-state batteries are particularly appealing for these applications, enabling more innovative product designs.

Key sectors and initial impacts

The initial commercial impact of solid-state batteries by 2025 will be felt across several critical sectors, transforming how energy is stored and utilized.

- Electric Vehicles: Introduction in premium models, offering extended range and quicker recharge times, setting new benchmarks for EV performance.

- Consumer Electronics: High-end devices benefiting from longer battery life and thinner designs due to higher energy density and improved safety.

- Specialized Industrial Equipment: Applications requiring robust and safe power sources, such as robotics or medical devices, where reliability is paramount.

Grid-scale energy storage, while perhaps seeing broader adoption slightly later, may also begin to incorporate solid-state battery components in pilot projects by 2025. The enhanced safety and modularity of solid-state systems make them attractive for supporting renewable energy integration and improving grid stability, especially in urban or sensitive environments.

The commercial applications by 2025 will serve as crucial validation points for solid-state battery technology. These early deployments will provide valuable real-world data, enabling further refinement and accelerating the journey towards widespread commercial success.

Investment and market growth projections

The burgeoning field of solid-state batteries is attracting significant investment, signaling strong confidence in its future market potential. Venture capital firms, established automotive giants, and national governments are pouring billions into research, development, and manufacturing infrastructure. This influx of capital is driving rapid advancements and paving the way for substantial market growth in the coming years.

Market analysts project a substantial increase in the solid-state battery market size, with some forecasts predicting it to reach tens of billions of dollars by the end of the decade. While 2025 might mark the beginning of commercial rollout, the subsequent years are expected to witness exponential growth as manufacturing scales up and costs decline. This growth will be fueled by increasing demand from the electric vehicle sector, renewable energy storage, and various consumer electronics applications.

Strategic partnerships between battery manufacturers, material suppliers, and end-users (like car companies) are becoming increasingly common. These collaborations are crucial for accelerating the development cycle, sharing expertise, and securing supply chains. Governments are also playing a vital role through grants, subsidies, and regulatory support, recognizing the strategic importance of this technology for energy independence and environmental sustainability.

Factors driving market expansion

Several key factors are contributing to the projected robust growth of the solid-state battery market.

- Environmental Regulations: Stricter emissions standards and mandates for renewable energy adoption are creating a strong pull for advanced energy storage solutions.

- Technological Advancements: Continuous breakthroughs in material science and manufacturing processes are improving performance and reducing costs, making solid-state batteries more competitive.

- Consumer Demand: Growing consumer preference for safer, longer-lasting, and faster-charging devices and vehicles is pushing manufacturers to adopt superior battery technologies.

The competitive landscape is also heating up, with numerous startups and established players vying for market leadership. This competition is fostering innovation and driving down prices, which will be essential for widespread adoption. The early movers who can successfully scale production and deliver reliable products will likely capture a significant share of this rapidly expanding market.

In summary, the substantial investment and positive market projections for solid-state batteries underscore their critical role in the future of energy storage. By 2025, we will likely see the foundations laid for a market set for considerable expansion, driven by technological maturity and increasing demand.

Challenges and future outlook beyond 2025

While the prospects for solid-state batteries by 2025 are promising, several challenges remain that will shape their long-term trajectory and broader adoption beyond that initial timeframe. Overcoming these hurdles will be crucial for solid-state technology to truly displace conventional lithium-ion batteries and fulfill its full potential across all sectors.

One of the primary challenges is the continued effort to reduce manufacturing costs. Although progress is being made, the current production costs for solid-state batteries are generally higher than for lithium-ion batteries. Achieving cost parity or even a competitive advantage will require further innovation in materials, manufacturing processes, and economies of scale. This is a complex undertaking that involves optimizing every step of the production chain, from raw material sourcing to final assembly.

Another significant hurdle is the long-term reliability and cycle life under real-world conditions. While laboratory tests show excellent performance, scaling this to millions of units operating in diverse environments presents its own set of challenges. Issues like electrode-electrolyte interface stability over thousands of charge-discharge cycles, and performance across a wide range of temperatures, need to be thoroughly validated. The industry is working diligently on these aspects, but extensive testing and refinement are still necessary.

Addressing long-term hurdles for widespread adoption

The path to widespread adoption beyond 2025 involves systematically tackling these persistent challenges.

- Cost Reduction: Developing cheaper materials and more efficient, high-volume manufacturing techniques to bring down the per-kilowatt-hour cost.

- Durability and Longevity: Enhancing the cycle life and calendar life of batteries under various operating conditions to match or exceed current lithium-ion standards.

- Supply Chain Development: Establishing robust and sustainable supply chains for novel solid electrolyte materials and lithium metal, ensuring availability and ethical sourcing.

Standardization and regulatory frameworks will also play a critical role. As solid-state batteries become more prevalent, there will be a need for industry-wide standards for performance, safety, and testing procedures. Regulatory bodies will also need to adapt to this new technology, ensuring its safe integration into existing infrastructure and consumer products.

Looking beyond 2025, the future of solid-state batteries is bright, but it requires sustained investment, continuous innovation, and collaborative efforts across the industry. The initial commercial deployments will provide invaluable experience, helping to refine the technology and address remaining challenges, ultimately paving the way for a new era of energy storage.

Innovations shaping the future of solid-state batteries

The rapid pace of innovation in solid-state battery technology is continually pushing the boundaries of what’s possible, promising even more advanced solutions beyond the initial commercial deployments in 2025. Researchers and engineers are exploring novel materials, architectures, and manufacturing techniques that could further enhance performance, reduce costs, and expand application possibilities.

One key area of innovation is the development of next-generation solid electrolytes. While current solid electrolytes offer significant advantages, ongoing research aims to discover materials with even higher ionic conductivity, better mechanical stability, and lower manufacturing costs. This includes exploring new ceramic compounds, polymer-ceramic hybrids, and sulfide-based materials, each with unique properties that could optimize battery performance for specific applications.

Another exciting frontier is the integration of artificial intelligence (AI) and machine learning (ML) into battery design and optimization. AI algorithms can analyze vast datasets from material experiments and simulations to predict optimal material compositions and battery architectures, significantly accelerating the research and development cycle. This data-driven approach allows for faster iteration and discovery of high-performance solid-state battery designs.

Emerging technologies and research directions

Several emerging technologies and research directions are poised to shape the long-term future of solid-state batteries.

- Advanced Anode Materials: Beyond lithium metal, research into silicon-based or other high-capacity anode materials could further boost energy density and reduce cost.

- 3D Battery Architectures: Designing batteries with complex 3D structures could increase surface area for ion exchange, leading to faster charging and higher power output in a smaller footprint.

- Self-Healing Materials: Integrating self-healing properties into solid electrolytes or electrodes could significantly extend battery life and improve robustness against degradation.

The development of advanced characterization techniques is also playing a crucial role. Tools like in-situ electron microscopy and spectroscopy allow researchers to observe battery processes at the atomic level, providing unprecedented insights into degradation mechanisms and guiding the development of more stable and efficient materials. This deep understanding is vital for overcoming the remaining scientific challenges.

These ongoing innovations underscore the dynamic nature of solid-state battery research. The continuous pursuit of better materials, smarter designs, and more efficient manufacturing processes ensures that solid-state batteries will continue to evolve, offering increasingly powerful and sustainable energy storage solutions well into the future, far beyond the initial milestones of 2025.

| Key Aspect | 2025 Outlook |

|---|---|

| Safety & Energy Density | Significantly enhanced over Li-ion, reducing fire risks and increasing capacity. |

| Commercial Applications | Initial deployment in premium EVs, high-end electronics, and specialized industrial uses. |

| Manufacturing & Cost | Challenges remain but breakthroughs in scaling and cost reduction are progressing. |

| Future Outlook | Continued innovation and investment promising wider adoption beyond 2025. |

Frequently asked questions about solid-state batteries

Solid-state batteries offer significantly enhanced safety due to non-flammable solid electrolytes, higher energy density allowing for longer range or battery life, and potentially faster charging speeds. They also promise a longer lifespan and more compact designs by eliminating bulky components.

While some initial commercial deployments, particularly in premium electric vehicles and high-end electronics, are anticipated around 2025, widespread commercial availability across all sectors might take until the late 2020s or early 2030s, as manufacturing scales and costs decrease.

Key challenges include reducing high manufacturing costs, ensuring long-term reliability and cycle life under diverse operating conditions, and scaling production to meet mass market demand. Developing robust supply chains for novel materials is also a significant hurdle.

Initially, solid-state batteries are expected to be more expensive than current lithium-ion batteries, likely appearing in premium EV models first. As production scales and technology matures, their cost is projected to decrease, potentially making EVs more affordable in the long term, especially considering their benefits.

Solid-state batteries can significantly improve grid-scale energy storage by offering safer, more compact, and potentially more efficient solutions. Their enhanced safety profile allows for deployment in urban areas, supporting better integration of intermittent renewable energy sources like solar and wind into the grid.

Conclusion

The advent of solid-state batteries marks a transformative period for energy storage, with 2025 shaping up to be a critical year for their initial commercial rollout. The promise of enhanced safety, superior energy density, and improved performance positions this technology as a formidable successor to conventional lithium-ion batteries. While manufacturing challenges and cost reduction remain key hurdles, ongoing innovations and significant investments are steadily paving the way for broader adoption. As we move beyond 2025, solid-state batteries are poised not just to incrementally improve existing applications but to fundamentally reshape industries, from electric vehicles to grid infrastructure, driving a more sustainable and electrified future.